Změna jazyka :

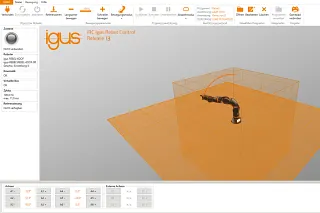

Software igus Robot Control

Programování, simulace a řízení robotů bez licence

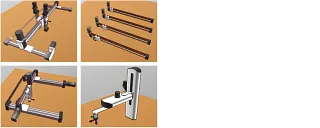

Software igus Robot Control umožňuje jednoduché a intuitivní programování a řízení robotů a usnadňuje začátky s automatizací. Díky modulární struktuře lze ovládat různé kinematiky robotů, např. delta roboty, lineární roboty a víceosé kloubové roboty. Pomocí softwaru lze simulovat jednotlivé pohyby robota na 3D povrchu - robot nemusí být pro tento krok připojen.

Co najdete na této stránce

Bezplatný software pro roboty

Příklady programování různých aplikací pomocí softwaru robota

- Jednoduché propojení robota s řídicím systémem

- Intuitivní ovládání s 3D rozhraním a digitálním dvojčetem umožňuje přímé provádění a kontrolu pohybových sekvencí.

- Možnost konfigurace rozhraní kamery přímo prostřednictvím řídicího systému a softwaru

- Programování delta, lineárních robotů, robotů SCARA a robotů s kloubovým ramenem

- Software umožňuje bezrizikové testování ještě před zakoupením

Systémové požadavky:

- Počítač s operačním systémem Windows 10

- Komunikace přes Ethernet nebo WLAN

- 500 MB volného místa na disku

Ukázkové programy, wiki a školení

Rozhraní

Rozhraní PLC

Rozhraní PLC (PLC = Programmable Logic Controller) umožňuje provádění základních funkcí a signalizaci stavů pomocí digitálních vstupů a výstupů. Kromě ovládání pomocí PLC umožňuje toto rozhraní také ovládání pomocí hardwarových tlačítek.

Digitální vstupy a výstupy

Programy robota lze načítat a spouštět a příkazy pro chapadla lze vysílat prostřednictvím digitálních vstupů nebo globálních signálů. To je užitečné například v případě, že je třeba vybrat program z dané nabídky pomocí tlačítek nebo instrukce CRI-GSig.

Modbus TCP/IP

Rozhraní Modbus TCP lze použít například k odesílání dat a instrukcí PLC do řídicího systému robota a k přijímání stavových informací.

Rozhraní CRI

Rozhraní CRI umožňuje odesílání složitých instrukcí a načítání informací a nastavení prostřednictvím rozhraní Ethernet s využitím protokolu TCP/IP. Řízení robotů igus používá toto rozhraní k připojení robotů s integrovaným řídicím systémem nebo jiných instancí řídicího systému.

Rozhraní kamery

Rozhraní kamery umožňuje používat detekci objektů a videokamery. Kamery pro detekci objektů rozpoznávají polohu a třídu objektů a přenášejí je, případně s obrazem, do řídicího systému. Řídicí systém vypočítá polohy v souřadnicovém systému robota z poloh objektů z kamery. Čisté videokamery přenášejí pouze obraz, a proto je lze použít pouze ke sledování pracovního prostoru, ale ne k detekci objektů.

Cloud

Rozhraní Cloud umožňuje sledovat robota prostřednictvím aplikace RobotDimension. Po aktivaci a přihlášení robot odesílá základní stavové informace a záběry z kamery do online služby. Uživatel může na webové stránce uvést své roboty a získat informace.

ROS, Matlab, LabView a mnoho dalších.

Integrace robotů do prostředí ROS. Dokumentace a balíčky pro hardwarovou komunikaci, Teleop a moveI

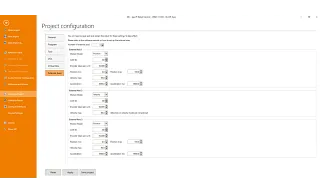

Konfigurace projektu

Gripper

Zde lze zadat sestavený nástroj. Změna nástroje vyžaduje opětovné načtení projektu nebo restartování integrovaného řídicího systému. Nové nástroje lze definovat jako konfigurační soubor v adresáři "Data/Tools."

Virtuální box

Rozsah pohybu robotického ramene je omezen nastavením virtuálního boxu. Tato funkce pomáhá předcházet mechanickému poškození a zjednodušuje programování v závislosti na aplikaci. Pokud je prováděn program, který porušuje virtuální box, je zastaven s chybovým hlášením.

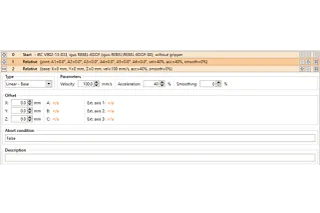

Vnější osa

Řídicí systém robota podporuje až 3 přídavné osy (v iRC se nazývají také "externí osy" ). Ty lze instalovat podle os robota a konfigurovat je prostřednictvím konfigurační oblasti iRC.

Program

Zde můžete definovat program robota a logiky, rychlost pohybu (v procentech maximální rychlosti), režim přehrávání a reakci na chyby programu.

Speciální kinematika

Řídicí systém robota lze přizpůsobit vašemu robotu pomocí digitálního dvojčete. Inverzní kinematiku nakonfigurujeme tak, aby vyhovovala vašemu projektovému podnikání.

Programování

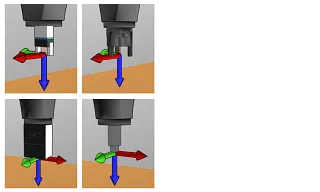

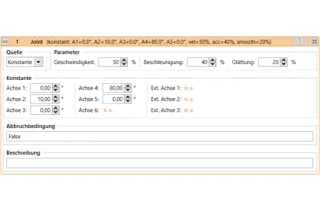

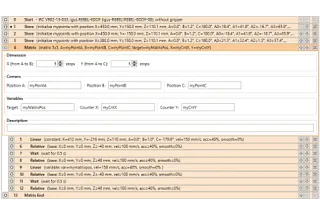

Pohyby v ose

Příkaz Joint přesune robota do absolutní cílové polohy, která je zadána v souřadnicích osy (např. úhel osy nebo poloha lineární osy). Výsledný pohyb TCP je obvykle křivka, nikoli přímka.

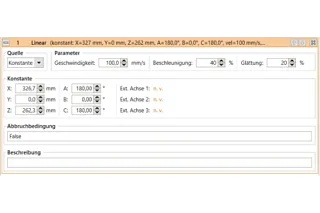

Lineární pohyb

Příkaz Lineární pohyb přesune robota do absolutní cílové polohy zadané v kartézských souřadnicích. Výsledný pohyb TCP probíhá po přímce.

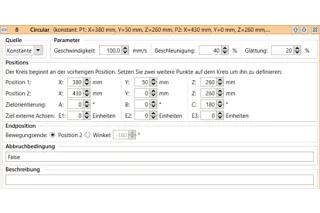

Kruhové pohyby

Pokyn "Kruhový pohyb" umožňuje pohyby po úplné nebo částečné kruhové dráze. Je kompatibilní s lineárními pohyby, takže přechod z lineárních pohybů a do nich může být vyhlazen.

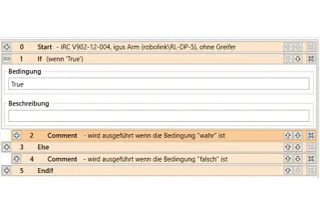

Podmínky

Podmínky lze použít v příkazech if-then-else, ve smyčkách a jako podmínky zrušení v příkazech pohybu. Podmínky mohou být kombinací digitálních vstupů, globálních signálů, logických operací a porovnání.

Výpočet matice

Pokyny pro výpočet mřížky počítají pozice zarovnané do mřížky, např. jako pozice pro uchopení nebo uložení pro úlohy paletizace.

Relativní

Příkaz Relativní umožňuje pohybovat robotem vzhledem k jeho aktuální poloze. Je přístupný prostřednictvím položek nabídky v části "Akce" → "Relativní pohyb".

Podprogramy

Podprogramy lze vyvolat pomocí příkazu sub. Cesta k souboru podprogramu je uvedena na "Název souboru". Je relativní vůči podsložce "Programy" složky iRC "Data".

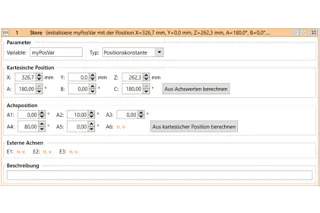

Proměnné a přístup k proměnným

V programu igus Robot Control a TinyCtrl jsou podporovány dva typy proměnných:

- Číselné proměnné: Tyto proměnné lze použít k uložení celých čísel nebo čísel s plovoucí desetinnou čárkou.

- Proměnné polohy: Tyto proměnné lze použít k uložení kartézských poloh a poloh kloubů. Zda bude taková proměnná interpretována jako kartézská poloha nebo poloha kloubu, závisí na kontextu.

Stáhnout software pro roboty

Bezlicenční software igus Robot Control je integrován do řídicího systému, a proto využívá standardizovaný koncept ovládání a konzistentní komunikační služby pro mnoho komponent jednoho systému. To znamená méně práce při plánování projektu a rychlejší uvedení do provozu.

- Vyzkoušejte si předem v softwaru veškerou kinematiku igus.

- S předprogramovanými projekty pro všechny roboty igus, jednoosé roboty a AGV.

- Intuitivní 3D rozhraní se simulací robota

Poradenské služby

Rád zodpovím vaše otázky osobne

HENNLICH s.r.o.+420 416 711 333Napsat e-mail

Preprava a konzultace

Osobne:

Pondelí až pátek od 7:00 do 16:00.

Online:

24h